Southeast Asia continues to rise as a global hub for industrial manufacturing, offering a wide range of opportunities for businesses. But each country brings its own set of advantages — and challenges. Let’s take a closer look:

🔹 Indonesia:

Advantages: Indonesia is the largest economy in SEA, offering a vast domestic market and many natural resources. The government is actively promoting industrial development, especially in automotive, electronics, and textiles.

Challenges: Infrastructure development is ongoing but still lags behind other countries. Supply chain disruptions can occur, and regulatory processes may be complex.

Workforce: Indonesia’s workforce is vast and skilled in large-scale production. There is growing investment in vocational training to improve precision and efficiency.

🔹 Vietnam:

Advantages: Vietnam has become popular for manufacturing, thanks to its competitive labor costs and increasing focus on high-tech industries. It’s ideal for electronics, garments, and assembly-line manufacturing.

Challenges: Though labor costs are low, increasing wages and potential over-reliance on exports present challenges. Infrastructure is improving but still has bottlenecks in logistics.

Workforce: The workforce is young, adaptable, and skilled in assembly work, with an increasing focus on advanced manufacturing techniques.

🔹 Thailand:

Advantages: With a well-developed infrastructure and strategic location, Thailand excels in the automotive, electronics, and machinery industries. It has a strong industrial base and incentives for foreign investments.

Challenges: Labor costs are higher than in neighboring countries, and political uncertainties remain.

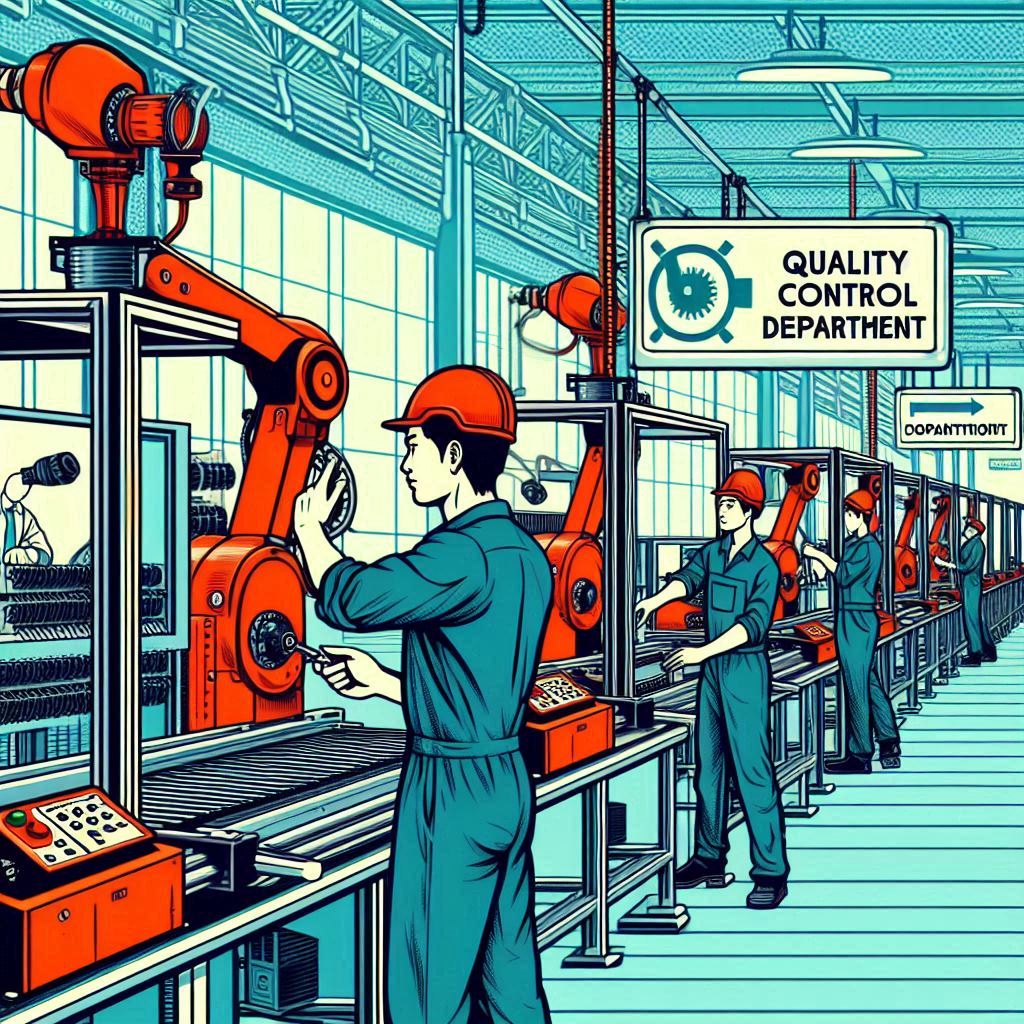

Workforce: Thailand’s workforce is well-versed in precision industries like automotive and electronics. The focus on lean manufacturing and ISO standards is widespread, making quality assurance a key strength.

🔹 Philippines:

Advantages: The Philippines is a major player in electronics, semiconductors, and BPO industries. High English proficiency and a young, tech-savvy population make it a strong choice for manufacturing and service operations.

Challenges: Infrastructure gaps and vulnerability to natural disasters can disrupt supply chains.

Workforce: Filipino workers are known for their adaptability and technical skills, particularly in electronics. Quality control systems are often stringent, especially in high-tech manufacturing.

Key Takeaway: Southeast Asia offers a diverse set of manufacturing hubs, each with distinct strengths and challenges. The workforce across the region is growing in both skills and specialization, especially in relation to quality control systems, but the focus and consistency can differ by country.

Which market aligns with your manufacturing strategy?

Industrial Manufacturing in Southeast Asia: Key Insights

Southeast Asia is a rising hub for industrial manufacturing, with each country offering unique strengths and challenges. Indonesia boasts natural resources and a vast market, Vietnam excels in low-cost, high-tech production, Thailand offers advanced infrastructure for precision industries, and the Philippines shines in electronics and BPO.